AMAL-SHAFT® – air expanding shafts

AMAL-SHAFT® is the original. The shaft was invented here in Åmål in the fifties and the concept has been world leading ever since. The concept is developed continuously so we can offer you the optimal solution.

PDF: Maintenance, PDF: User instructions

You’ll find our standard collection below

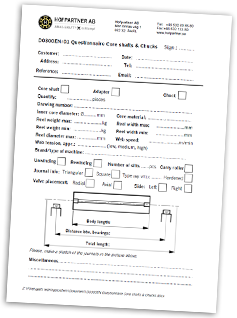

Download our questionnaire for Core Shafts & Chucks.

E-mail to info@hofpartner.se

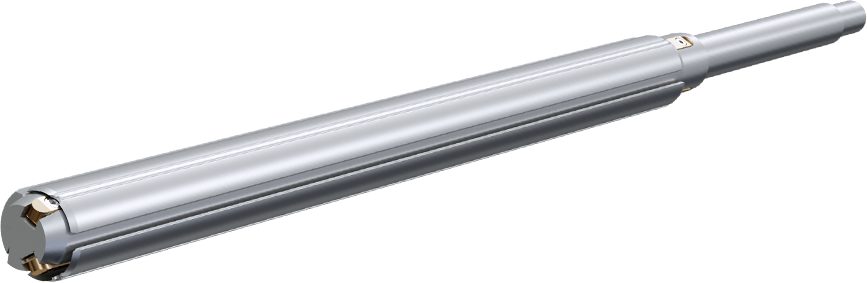

S&T – Solid or Tube section, milled grooves

- Very strong

- Minimal deflection

- For core diameter: Ø18mm to Ø600mm

- Groove widths 9, 16, 20 and 33 mm

- Number of grooves varies according to application

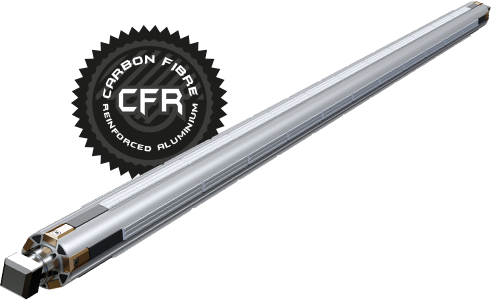

TPPC – Thin Profile Pitch Centring

- Carbon fibre reinforced aluminium profile

- Light and strong

- Durable

- For cores: Ø70mm and Ø76mm (3”)

- Groove width 20 mm

TPC – Thin Profile Centring

- Ultra light weight aluminium profile

- Weight optimized profile

- For cores: Ø70mm and Ø76mm (3”)

- Groove width 20 mm

PC – Profile Centring

- Solid aluminium profile

- Very cost effective

- For cores: Ø70mm and Ø76mm (3”)

- Groove width 20 mm

PTC 150 – Profile Tube Centring

- Light weight

- Available as ultra light weight (middle)

- Optimized profile

- For cores: Ø150mm and Ø152,4mm (6”)

- Centring ledges adaptable for Ø148,5 – Ø153mm

- Groove width 20 mm

Browse our air shaft and chucks broschure

AMAL-SHAFT® OPTIONS

Here is a selection of options for our expanding air axes

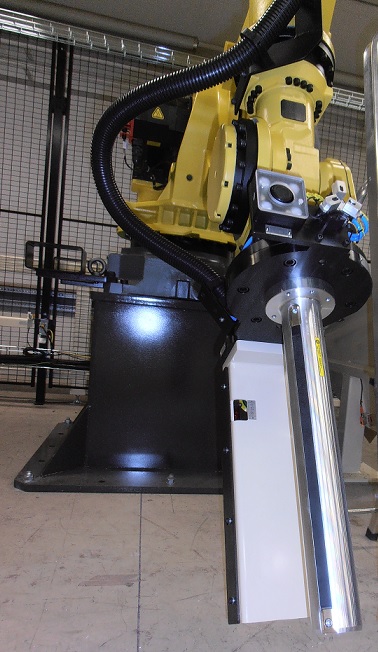

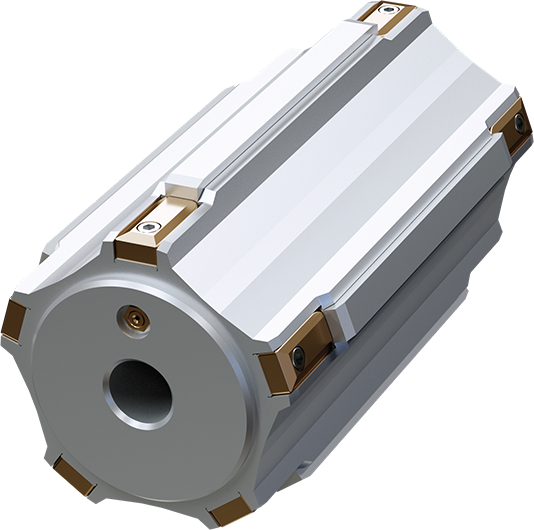

Multi Body

- Extended Life Bearing (XLB) is standard

- Easy maintenance

- Active centring as option

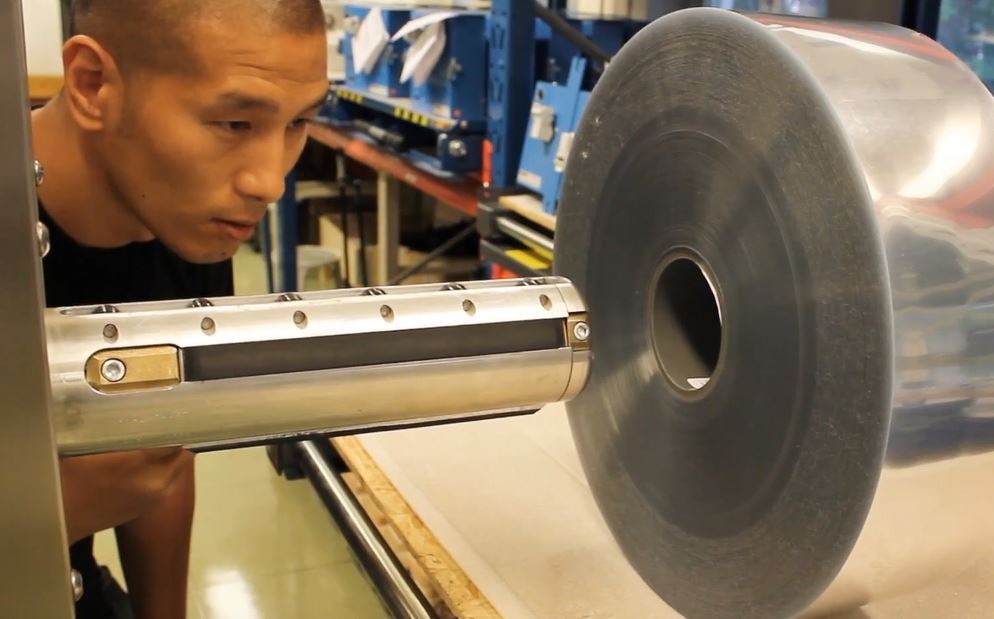

Together with our customers we have developed a unique concept for rewinding multiple rolls on long slim expanding shafts with two or more bodies. Our concept is both robust and easy-maintenance.

This type of shaft is used mainly in plastic foil industries.

.

Extended Life Bearing – XLB

Standard on Hofpartners Multi Body-applications.

Maximum production with minimum maintenance. Doubles the production and increases the life span of the bearing tenfold.

“We implemented XLB and doubled our production”

Testimony of a satisfied customer

Roll-lifting shaft

- Activated pneumatically

- Inverted expansion as option (for added safety)

- Sawtooth modelled expanding element in metal or rubber

- Dimensions according to your wishes

Differential air shafts

Friction or differential shafts are used when winding multiple webs or rolls. They have the characteristic of taking up the differences in length that occur across the width of the web. Without a friction shaft, some of the webs will get slack which can result in rolls that have to be discarded.

The shaft rotates at a few percent higher speed and the rolls “slip” on the shaft. There are many different principles for how this works. On the simpler variants, the roller’s sleeve slips against the expander elements on the friction shaft. On the sophisticated variants, sleeves slide on the shaft itself.

We are developing a new and unique concept for frictions shafts. Our aim is to introduce it to the market in the beginning of Q2 2022.

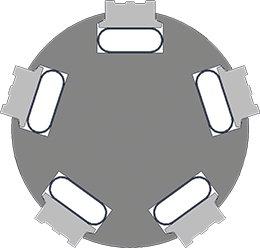

Centring

If optimum centring of the core on the shaft is required, we can offer both passive and active centring.

Passive centring requires that you always use the same core diameter, as the shaft is adapted to this. If you desire a perfect centring regardless of the inner diameter of the sleeve, we also offer our mechanical shaft Schlumpf SF.

Read more about our mechanically centering shaft (Schlumpf SF)

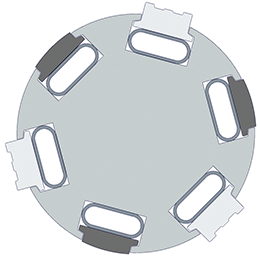

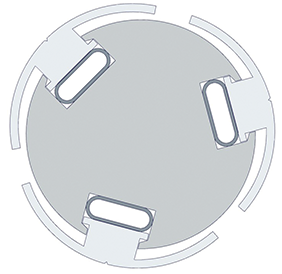

Active centring

- Perfect centring

- The expanding elements return after releasing the pressure

- Expanding elements are adapted to the inner diameter of the core

- Very easy to mount and demount the cores

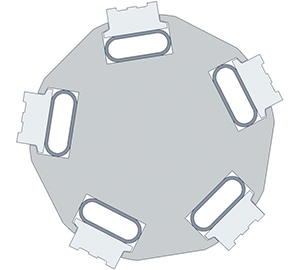

Passive centring

- The “peaks” of the body center the core

- The shape of the body makes it easy to mount and demount the cores despite the tight fit

- The “peaks” of the body are adapted to the inner diameter of the core

Safety valve – eliminate downtime

To eliminate expensive downtime, we have a system of separate valves for each expanding groove in the shaft. A special air nozzle is required. This nozzle has a shuttle that determines whether the roller shaft will be inflated or deflated. See picture below.

We have been delivering this system to satisfied customers for over 30 years.

Air expanding shafts for coreless winding

- Standardprofiles available for ø 38/50/70/76/100 mm

- We manufacture other diameters on demand

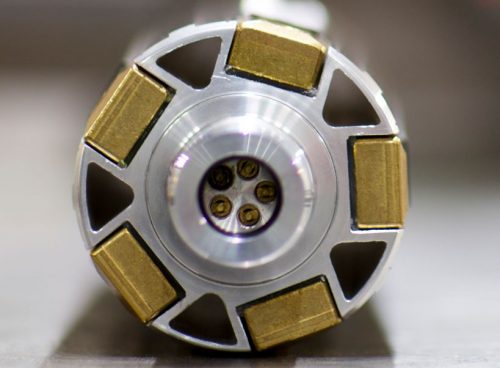

Expanding elements/slats/lugs

- Aluminium, rubber, steel

- Grooved lengthways

- Whole length or smaller (so-called multi)

- Wing-shaped (for coreless winding)

Adapters

We have a large assortment of adapters and can produce them after your specific needs.

Browse our air shaft and chucks broschure

Download our questionnaire for Core Shafts & Chucks and e-mail to info@hofpartner.se